David - "When it comes to a Follow Focus there is no such thing as too rigid."

|

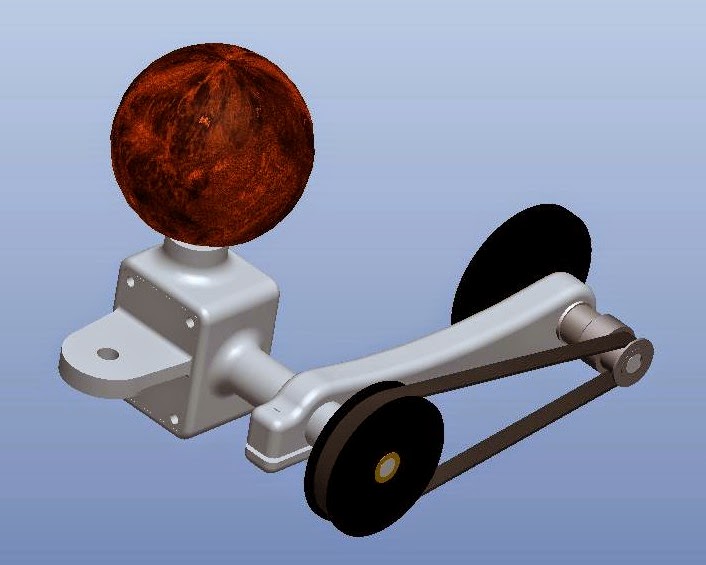

| We will be working in BLACK ANODIZED 6061 aluminum Denis left the aluminum clean so you could see the design more clearly. |

Designed from the ground up for handheld camera work, Denis Egli has taken my prototype and made magic. This design allows you to flip the drive shaft from back to front or one side of the lens to the other by rotating or moving the Arri style rosette plate from one side to the other and them locking it in with four 3mm cap screws. With this adjustability you could use two, one for focus and one for zoom. The open side is then capped it off with a black walnut plate to protect the brass beveled gears this will be attached with four brass button cap machine screws.

Designed from the ground up for handheld camera work, Denis Egli has taken my prototype and made magic. This design allows you to flip the drive shaft from back to front or one side of the lens to the other by rotating or moving the Arri style rosette plate from one side to the other and them locking it in with four 3mm cap screws. With this adjustability you could use two, one for focus and one for zoom. The open side is then capped it off with a black walnut plate to protect the brass beveled gears this will be attached with four brass button cap machine screws.  The drive shafts are made from 1/4' D-rod which come in every imaginable length (at very reasonable prices) so you can extend the pitched gear for the focus ring to exactly where it needs to go. This is one of the major unique features which allows the operator to place the HF1 just where you want it. The shafts themselves are are threaded through 3 flanged ball bearings at the gear box and 2 on the drive arm, for smooth and ridged operation. Attached directly to the 15/15 bracket you will have just the perfect angle allowing your hand and wrist to position themselves for perfect load bearing ergonomic operation. We will also make a single rod mount with a Arri style rosette so you can place the ergocine HF1 independently form the bracket.

The drive shafts are made from 1/4' D-rod which come in every imaginable length (at very reasonable prices) so you can extend the pitched gear for the focus ring to exactly where it needs to go. This is one of the major unique features which allows the operator to place the HF1 just where you want it. The shafts themselves are are threaded through 3 flanged ball bearings at the gear box and 2 on the drive arm, for smooth and ridged operation. Attached directly to the 15/15 bracket you will have just the perfect angle allowing your hand and wrist to position themselves for perfect load bearing ergonomic operation. We will also make a single rod mount with a Arri style rosette so you can place the ergocine HF1 independently form the bracket. |

| Rosette, bolts and lock down not shown. |

Once we have knocked out some beta's we will send it around for evaluation, one of the main things we need to see is if the Sphere needs more resistance. We are kicking around ideas for a way to create some adjustable resistance. In addition we will have a option for a dry erase disk to attach to the sphere and reference point mounted on the gear box.

The next step will be a Kickstarter campaign to presell 50 to 100 units at a discount, Denis is bring the design over to Chuck (the shop manager) to get some pricing but we are doing everything in our power to keep this affordable.

It is now more important then ever for us to get our Facebook likes up so please help us with this exciting new project by liking us at ERGOCINE.

It is now more important then ever for us to get our Facebook likes up so please help us with this exciting new project by liking us at ERGOCINE.Thank you.

David

No comments:

Post a Comment